Blogroll

Control chart

We will discuss the historys of a control chart using minitab and you can apply to many

aspects of the work

You can use control charts to track process statistics over time and to detect the presence

of special causes.Minitab plots a process statistic, such as a subgroup mean, individual

observation,

weighted statistic, or number of defects, versus sample number or time.

Minitab draws the:

• Center line at the average of the statistic by default

• Upper control limit, 3σ above the center line by default

• Lower control limit, 3σ below the center line by default

Special causes result in variation that can be detected and controlled. Examples include

differences in supplier, shift, or day of the week. Common cause variation, on the other

hand, is inherent in the process. A process is in control when only common causes − not

special causes − affect the process output.

A process is in control when points fall within the bounds of the control limits, and the points

do not display any nonrandom patterns. Use the tests for special causes offered with

Minitab's control charts to detect nonrandom patterns in your data.

You can also perform a Box-Cox transformation on non-normal data.

When a process is in control, you can use control charts to estimate process parameters

needed to determine capability.

Minitab offers a variety of options for customizing your control charts:

• See Control Chart Options for options specific to control charts, such as using stages

and tests for special causes.

• See Control Chart Display Options for options that are available before graph creation, such

as subsetting your data and changing the control chart's title.

• See Graph Editing Overview for options that are available after graph creation, such

as changing font size and figure location.

Exsamples of Control chart

The following examples illustrate how to generate control charts with Minitab.

Choose an example below:

1. Box-Cox transformation

2. X-bar and R chart

3. X-bar and S chart

4. I-MR-R/S Chart

5. X-Bar Chart

6. R Chart

7. S chart

8. zone chart

9. I-MR chart

10. Z-MR chart

11. Individuals chart

12. moving range chart

13. P Chart

14. NP chart

15. C chart

16. U chart

Referances: www.minitab.com

We will discuss the historys of a control chart using minitab and you can apply to many

aspects of the work

You can use control charts to track process statistics over time and to detect the presence

of special causes.Minitab plots a process statistic, such as a subgroup mean, individual

observation,

weighted statistic, or number of defects, versus sample number or time.

Minitab draws the:

• Center line at the average of the statistic by default

• Upper control limit, 3σ above the center line by default

• Lower control limit, 3σ below the center line by default

|

| Control chart |

Special causes result in variation that can be detected and controlled. Examples include

differences in supplier, shift, or day of the week. Common cause variation, on the other

hand, is inherent in the process. A process is in control when only common causes − not

special causes − affect the process output.

A process is in control when points fall within the bounds of the control limits, and the points

do not display any nonrandom patterns. Use the tests for special causes offered with

Minitab's control charts to detect nonrandom patterns in your data.

You can also perform a Box-Cox transformation on non-normal data.

When a process is in control, you can use control charts to estimate process parameters

needed to determine capability.

Minitab offers a variety of options for customizing your control charts:

• See Control Chart Options for options specific to control charts, such as using stages

and tests for special causes.

• See Control Chart Display Options for options that are available before graph creation, such

as subsetting your data and changing the control chart's title.

• See Graph Editing Overview for options that are available after graph creation, such

as changing font size and figure location.

Exsamples of Control chart

The following examples illustrate how to generate control charts with Minitab.

Choose an example below:

1. Box-Cox transformation

2. X-bar and R chart

3. X-bar and S chart

4. I-MR-R/S Chart

5. X-Bar Chart

6. R Chart

7. S chart

8. zone chart

9. I-MR chart

10. Z-MR chart

11. Individuals chart

12. moving range chart

13. P Chart

14. NP chart

15. C chart

16. U chart

Referances: www.minitab.com

Symmetry Plot

Symmetry plots can be used to assess whether sample data come from a symmetric distribution. Many statistical procedures assume that data come from a normal distribution. However, many procedures are robust to violations of normality, so having data from a symmetric distribution is often sufficient. Other procedures, such as nonparametric methods, assume symmetric distributions rather than normal distributions.

Therefore, a symmetry plot is a useful tool in many circumstances.

When use to Symmetry Plot

When the sample data follow a symmetric distribution, the X and Y coordinates will be approximately equal for all points and the data will fall in a straight line. Minitab draws a line on the plot to represent exact X-Y equality (a perfectly symmetric sample).

By comparing the data points to the line, you can assess the degree of symmetry present in the data. The more symmetric the data, the closer the points will be to the line. Even with normally distributed data, you can expect to see runs of points above or below the line. The important thing to look for is whether the points remain close to or parallel to the line, versus the points diverging from the line. You can detect the following asymmetric conditions.

Mark to Symmetry Plot

we will carify by sample of Minitab sample. Before doing further analyses, you would like to determine whether or not the sample data come from a symmetric

distribution.

1.Open the worksheet EXH_QC.MTW.

3.Choose Stat > Quality Tools > Symmetry Plot.

4. In Variables, enter Faults. Click OK.

5. After that click OK that show Graph window output below.

Interpreting the results

Notice the few points above the line in the upper right corner. These points indicate skewness in the left tail of the

distribution. You can also see this skewness in the histogram.

Refer by www.minitab.com

|

| Symmetry Plot |

Symmetry plots can be used to assess whether sample data come from a symmetric distribution. Many statistical procedures assume that data come from a normal distribution. However, many procedures are robust to violations of normality, so having data from a symmetric distribution is often sufficient. Other procedures, such as nonparametric methods, assume symmetric distributions rather than normal distributions.

Therefore, a symmetry plot is a useful tool in many circumstances.

When use to Symmetry Plot

When the sample data follow a symmetric distribution, the X and Y coordinates will be approximately equal for all points and the data will fall in a straight line. Minitab draws a line on the plot to represent exact X-Y equality (a perfectly symmetric sample).

By comparing the data points to the line, you can assess the degree of symmetry present in the data. The more symmetric the data, the closer the points will be to the line. Even with normally distributed data, you can expect to see runs of points above or below the line. The important thing to look for is whether the points remain close to or parallel to the line, versus the points diverging from the line. You can detect the following asymmetric conditions.

Mark to Symmetry Plot

we will carify by sample of Minitab sample. Before doing further analyses, you would like to determine whether or not the sample data come from a symmetric

distribution.

1.Open the worksheet EXH_QC.MTW.

3.Choose Stat > Quality Tools > Symmetry Plot.

4. In Variables, enter Faults. Click OK.

5. After that click OK that show Graph window output below.

|

| Symmetry Plot |

Interpreting the results

Notice the few points above the line in the upper right corner. These points indicate skewness in the left tail of the

distribution. You can also see this skewness in the histogram.

Refer by www.minitab.com

Multi-Vari Chart

Minitab 16 can draws multi-vari charts for up to four factors. Multi-vari charts are a way of presenting analysis of variance data in a graphical form providing a "visual" alternative to analysis of variance. These charts may also be used in the preliminary

stages of data analysis to get a look at the data. The chart displays the means at each factor level for every factor.

When do you use Multi Vari Chart

You need one numeric column for the response variable and up to four numeric, text, or date/time factor columns. Each row contains the data for a single observation.

Text categories (factor levels) are processed in alphabetical order by default. If you wish, you can define your own order −see Ordering Text Categories.Minitab automatically omits missing data from the calculations.

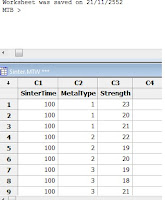

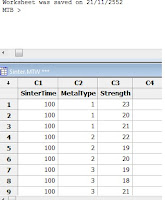

Example of a Multi-Vari Chart

You are responsible for evaluating the effects of sintering time on the compressive strength of three different metals. Compressive strength was measured for five specimens for each metal type at each of the sintering times: 100 minutes,150 minutes, and 200 minutes. Before you engage in a full data analysis, you want to view the data to see if there are any visible trends or interactions by creating a multi-vari chart.

1 Open the worksheet SINTER.MTW.

you will see to data ==>

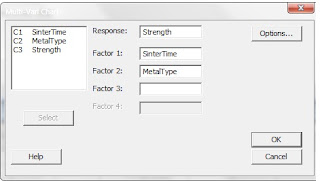

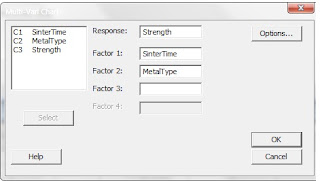

2 Choose Stat > Quality Tools > Multi-Vari Chart.

Response: Enter the column containing the response (measurement) data.

Factor 1: Enter the factor level column.

Factor 2: Enter an additional factor level column.

Factor 3: Enter an additional factor level column.

Factor 4: Enter an additional factor level column.

3. In Response, enter Strength.

In Response, enter the column containing the response (measurement) data.

4 In Factor 1, enter SinterTime. In Factor 2, enter MetalType. Click OK.

In Factor 1, enter a factor level column.

In Factor 1, enter a factor level column.

Interpreting the results

The multi-vari chart indicates that an interaction exists between the type of metal and the length of time it is sintered. The greatest compressive strength for Metal Type 1 is obtained by sintering for 100 minutes, for Metal Type 2 sintering for 150 minutes, and for Metal Type 3 sintering for 200 minutes.To quantify this interaction, you could further analyze this data using techniques such as analysis of variance or general linear model.

Learn more... Run chart

|

| Multi-Vari Chart |

stages of data analysis to get a look at the data. The chart displays the means at each factor level for every factor.

When do you use Multi Vari Chart

You need one numeric column for the response variable and up to four numeric, text, or date/time factor columns. Each row contains the data for a single observation.

Text categories (factor levels) are processed in alphabetical order by default. If you wish, you can define your own order −see Ordering Text Categories.Minitab automatically omits missing data from the calculations.

Example of a Multi-Vari Chart

You are responsible for evaluating the effects of sintering time on the compressive strength of three different metals. Compressive strength was measured for five specimens for each metal type at each of the sintering times: 100 minutes,150 minutes, and 200 minutes. Before you engage in a full data analysis, you want to view the data to see if there are any visible trends or interactions by creating a multi-vari chart.

1 Open the worksheet SINTER.MTW.

you will see to data ==>

2 Choose Stat > Quality Tools > Multi-Vari Chart.

Response: Enter the column containing the response (measurement) data.

Factor 1: Enter the factor level column.

Factor 2: Enter an additional factor level column.

Factor 3: Enter an additional factor level column.

Factor 4: Enter an additional factor level column.

3. In Response, enter Strength.

In Response, enter the column containing the response (measurement) data.

4 In Factor 1, enter SinterTime. In Factor 2, enter MetalType. Click OK.

In Factor 1, enter a factor level column.

In Factor 1, enter a factor level column.- If you have more than one factor, enter columns in Factor 2, Factor 3, or Factor 4 as needed.

- If you like, use any dialog box items, then click OK.

|

| Multi-Vari Chart |

The multi-vari chart indicates that an interaction exists between the type of metal and the length of time it is sintered. The greatest compressive strength for Metal Type 1 is obtained by sintering for 100 minutes, for Metal Type 2 sintering for 150 minutes, and for Metal Type 3 sintering for 200 minutes.To quantify this interaction, you could further analyze this data using techniques such as analysis of variance or general linear model.

Learn more... Run chart