Blogroll

I-MR-R/S Chart

Variables control charts for individuals plot statistics from measurement data, such as length or pressure, for individuals data. Variables control charts for subgroups, time-weighted charts, and multivariate charts also plot measurement data.

Attributes control charts plot count data, such as the number of defects or defective units.

For more information about control charts, see Control Charts Overview.

Choosing a variables control chart for individuals

Minitab offers five variables control charts:

• I-MR − an Individuals chart and Moving Range chart displayed in one window

• Z-MR − a chart of standardized individual observations and moving ranges from short run processes

• Individuals − a chart of individual observations

• Moving Range − a chart of moving ranges

Individuals−Moving Range Chart

An I-MR chart is an Individuals chart and Moving Range chart in the same graph window. The Individuals chart is drawn in the upper half of the screen; the Moving Range chart in the lower half. Seeing both charts together allows you to track both the process level and process variation at the same time, as well as detect the presence of special causes.

See [29] for a discussion of how to interpret joint patterns in the two charts.

By default, I-MR Chart estimates the process variation, σ, with MRbar / d2, the average of the moving range divided by an unbiasing constant. The moving range is of length 2, since consecutive values have the greatest chance of being alike.

You can also estimate σ using the median of the moving range, change the length of the moving range, or enter a

historical value for σ.

Example of I-MR chart

As the distribution manager at a limestone quarry, you want to monitor the weight (in pounds) and variation in the 45 batches of limestone that are shipped weekly to an important client. Each batch should weigh approximately 930 pounds.

You previously created a Moving Average chart. Now you want to examine the same data using an individuals and moving range chart.

How to make the I-MR Chart

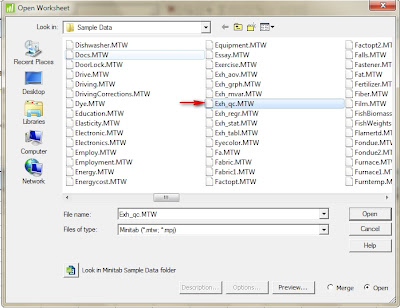

1 Open the worksheet EXH_QC.MTW.

2 Choose Stat > Control Charts > Variables Charts for Individuals > I-MR.

3 In Variables, enter Weight.

4 Click I-MR Options, then click the Tests tab.

5 Choose Perform all tests for special causes, then click OK in each dialog box.

6. Click OK and we will see I-MR chart

Interpreting the results

The individuals chart shows 6 points outside the control limits and 22 points inside the control limits exhibiting a nonrandom pattern, suggesting the presence of special causes. The moving range chart shows one point above the control limit. You should closely examine the quarry's processes to improve control over the weight of limestone

shipments.

Reference by www.minitab.com

|

| I-MR chart |

Attributes control charts plot count data, such as the number of defects or defective units.

For more information about control charts, see Control Charts Overview.

Choosing a variables control chart for individuals

Minitab offers five variables control charts:

• I-MR − an Individuals chart and Moving Range chart displayed in one window

• Z-MR − a chart of standardized individual observations and moving ranges from short run processes

• Individuals − a chart of individual observations

• Moving Range − a chart of moving ranges

Individuals−Moving Range Chart

An I-MR chart is an Individuals chart and Moving Range chart in the same graph window. The Individuals chart is drawn in the upper half of the screen; the Moving Range chart in the lower half. Seeing both charts together allows you to track both the process level and process variation at the same time, as well as detect the presence of special causes.

See [29] for a discussion of how to interpret joint patterns in the two charts.

By default, I-MR Chart estimates the process variation, σ, with MRbar / d2, the average of the moving range divided by an unbiasing constant. The moving range is of length 2, since consecutive values have the greatest chance of being alike.

You can also estimate σ using the median of the moving range, change the length of the moving range, or enter a

historical value for σ.

Example of I-MR chart

As the distribution manager at a limestone quarry, you want to monitor the weight (in pounds) and variation in the 45 batches of limestone that are shipped weekly to an important client. Each batch should weigh approximately 930 pounds.

You previously created a Moving Average chart. Now you want to examine the same data using an individuals and moving range chart.

How to make the I-MR Chart

1 Open the worksheet EXH_QC.MTW.

|

| I-MR chart-1 |

|

| I-MR chart-2 |

|

| I-MR chart-3 |

4 Click I-MR Options, then click the Tests tab.

|

| I-MR chart-4 |

5 Choose Perform all tests for special causes, then click OK in each dialog box.

|

| I-MR chart-5 |

|

| I-MR chart-6 |

|

| I-MR chart |

Interpreting the results

The individuals chart shows 6 points outside the control limits and 22 points inside the control limits exhibiting a nonrandom pattern, suggesting the presence of special causes. The moving range chart shows one point above the control limit. You should closely examine the quarry's processes to improve control over the weight of limestone

shipments.

Reference by www.minitab.com

X-bar and S chart

Variables Control Charts for Subgroups Overview data

Variables control charts for subgroups plot statistics from measurement data, such

as length or pressure

, for subgroup data. Variables control charts for individuals,

time-weighted charts, and multivariate charts also plot measurement data.

Attributes control charts plot count data, such as the number of defects or defective units.

For more information about control charts, see Control Charts Overview.

Choosing a variables control chart for subgroups

Minitab offers five variables control charts:

• X-bar and R − an X-bar chart and R chart displayed in one window

• X-bar and S − an X-bar chart and S chart displayed in one window

• I-MR-R/S (Between/Within) − a three-way control chart that uses both

between-subgroup and within-subgroup variation. An I-MR-R/S chart consists of

an I chart, a MR chart, and a R or S chart.

• X-bar − a chart of subgroup means

• R − a chart of subgroup ranges

• S − a chart of subgroup standard deviations

• Zone − a chart of the cumulative scores based on each point's distance

from the center line

The I-MR-R/S (Between/Within) chart requires that you have two or more

observations in at least one subgroup. Subgroups do not need to be the same size.

Minitab calculates summary statistics for each subgroup, which are plotted

on the chart and used to estimate process parameters.

Example of X-bar and S chart

You are conducting a study on the blood glucose levels of 9 patients who are on strict

diets and exercise routines. To monitor the mean and standard deviation of

the blood glucose levels of your patients, create an X-bar and S chart. You take a blood

glucose reading every day for each patient for 20 days.

How to make to X-bar and S chart

1 Open the worksheet BLOODSUGAR.MTW.

2 Choose Stat > Control Charts > Variables Charts for Subgroups > Xbar-S.

3 Choose All observations for a chart are in one column, then enter Glucoselevel.

4 In Subgroup sizes, enter 9. Click OK.

5.we will get to X-bar and S chart below.

Interpreting the results

The glucose level means and standard deviations over the 10-day period fall

within the control limits. The glucose level and its variability are in control for

the nine patients on the diet and exercise program.

Reference by www.minitab.com

Variables Control Charts for Subgroups Overview data

|

| X-bar and S chart |

as length or pressure

, for subgroup data. Variables control charts for individuals,

time-weighted charts, and multivariate charts also plot measurement data.

Attributes control charts plot count data, such as the number of defects or defective units.

For more information about control charts, see Control Charts Overview.

Choosing a variables control chart for subgroups

Minitab offers five variables control charts:

• X-bar and R − an X-bar chart and R chart displayed in one window

• X-bar and S − an X-bar chart and S chart displayed in one window

• I-MR-R/S (Between/Within) − a three-way control chart that uses both

between-subgroup and within-subgroup variation. An I-MR-R/S chart consists of

an I chart, a MR chart, and a R or S chart.

• X-bar − a chart of subgroup means

• R − a chart of subgroup ranges

• S − a chart of subgroup standard deviations

• Zone − a chart of the cumulative scores based on each point's distance

from the center line

The I-MR-R/S (Between/Within) chart requires that you have two or more

observations in at least one subgroup. Subgroups do not need to be the same size.

Minitab calculates summary statistics for each subgroup, which are plotted

on the chart and used to estimate process parameters.

Example of X-bar and S chart

You are conducting a study on the blood glucose levels of 9 patients who are on strict

diets and exercise routines. To monitor the mean and standard deviation of

the blood glucose levels of your patients, create an X-bar and S chart. You take a blood

glucose reading every day for each patient for 20 days.

How to make to X-bar and S chart

1 Open the worksheet BLOODSUGAR.MTW.

|

| X-bar and S chart 2 |

2 Choose Stat > Control Charts > Variables Charts for Subgroups > Xbar-S.

|

| X-bar and S chart 3 |

3 Choose All observations for a chart are in one column, then enter Glucoselevel.

|

| X-bar and S chart 4 |

|

| X-bar and S chart 5 |

4 In Subgroup sizes, enter 9. Click OK.

|

| X-bar and S chart 6 |

5.we will get to X-bar and S chart below.

|

| X-bar and S chart 7 |

Interpreting the results

The glucose level means and standard deviations over the 10-day period fall

within the control limits. The glucose level and its variability are in control for

the nine patients on the diet and exercise program.

Reference by www.minitab.com

X-bar and R chart

Displays a control chart for subgroup means (an X-bar chart) and a control chart for subgroup

ranges (an R chart) in the same graph window. The X-bar chart is drawn in the upper half

of the screen; the R chart in the lower half. Seeing both charts together allows you to track

both the process level and process variation at the same time, as well as detect the

presence of special causes.

X-bar and R charts are typically used to track the process level and process variation

for samples of size 8 or less, while

X-bar and S charts are used for larger samples.

By default, Minitab's X-bar and R chart bases the estimate of the process variation, σ,

on the average of the subgroup ranges. You can also use a pooled standard deviation,

or enter a historical value for σ.

To display an X-bar and R chart

1 Choose Stat > Control Charts > Variables Charts for Subgroups > Xbar-R.

2 Do one of the following:

• If subgroups are in one or more columns, choose All observations for a chart are in

one column, then enter one or more columns. In Subgroup sizes, enter a number or

a column of subscripts.

• If subgroups are in rows, choose Observations for a subgroup are in one row of

columns, then enter a series of columns.

3 If you like, use any dialog box options, then click OK.

Example of X-bar and R chart

You work at an automobile engine assembly plant. One of the parts, a camshaft,

must be 600 mm +2 mm long to meet engineering specifications.

There has been a chronic problem with camshaft length being out of specification, which

causes poor-fitting assemblies, resulting in high scrap and rework rates.

Your supervisor wants to run X-bar and R charts to monitor this characteristic,

so for a month, you collect a total of 100 observations (20 samples of 5 camshafts each)

from all the camshafts used at the plant, and 100 observations from each of your suppliers.

First you will look at camshafts produced by Supplier 2.

How to make x-bar and R chart

1 Open the worksheet CAMSHAFT.MTW.

2 Choose Stat > Control Charts > Variables Charts for Subgroups > Xbar-R.

3 Choose All observations for a chart are in one column, then enter Supp2.

4 In Subgroup sizes, enter 5. Click OK.

5.we will get to X-bar and R chart below.

Interpreting the results

The center line on the X-bar chart is at 600.23, implying that your process is falling

within the specification limits, but two of the points fall outside the control limits,

implying an unstable process. The center line on the R chart, 3.890, is also

quite large considering the maximum allowable variation is +2 mm.

There may be excess variability in your process.

Note: Test Results for Xbar Chart of Supp2

TEST 1. One point more than 3.00 standard deviations from center line.

Test Failed at points: 2, 14

* WARNING

* If graph is updated with new data, the results above may no

* longer be correct.

References by www.minitab.com

Displays a control chart for subgroup means (an X-bar chart) and a control chart for subgroup

ranges (an R chart) in the same graph window. The X-bar chart is drawn in the upper half

of the screen; the R chart in the lower half. Seeing both charts together allows you to track

both the process level and process variation at the same time, as well as detect the

presence of special causes.

|

| X-bar and R chart |

X-bar and R charts are typically used to track the process level and process variation

for samples of size 8 or less, while

X-bar and S charts are used for larger samples.

By default, Minitab's X-bar and R chart bases the estimate of the process variation, σ,

on the average of the subgroup ranges. You can also use a pooled standard deviation,

or enter a historical value for σ.

To display an X-bar and R chart

1 Choose Stat > Control Charts > Variables Charts for Subgroups > Xbar-R.

2 Do one of the following:

• If subgroups are in one or more columns, choose All observations for a chart are in

one column, then enter one or more columns. In Subgroup sizes, enter a number or

a column of subscripts.

• If subgroups are in rows, choose Observations for a subgroup are in one row of

columns, then enter a series of columns.

3 If you like, use any dialog box options, then click OK.

Example of X-bar and R chart

You work at an automobile engine assembly plant. One of the parts, a camshaft,

must be 600 mm +2 mm long to meet engineering specifications.

There has been a chronic problem with camshaft length being out of specification, which

causes poor-fitting assemblies, resulting in high scrap and rework rates.

Your supervisor wants to run X-bar and R charts to monitor this characteristic,

so for a month, you collect a total of 100 observations (20 samples of 5 camshafts each)

from all the camshafts used at the plant, and 100 observations from each of your suppliers.

First you will look at camshafts produced by Supplier 2.

How to make x-bar and R chart

1 Open the worksheet CAMSHAFT.MTW.

|

| X-bar and R chart -1 |

2 Choose Stat > Control Charts > Variables Charts for Subgroups > Xbar-R.

|

| X-bar and R chart -2 |

3 Choose All observations for a chart are in one column, then enter Supp2.

|

| X-bar and R chart -3 |

4 In Subgroup sizes, enter 5. Click OK.

|

| X-bar and R chart -4 |

5.we will get to X-bar and R chart below.

|

| X-bar and R chart -5 |

The center line on the X-bar chart is at 600.23, implying that your process is falling

within the specification limits, but two of the points fall outside the control limits,

implying an unstable process. The center line on the R chart, 3.890, is also

quite large considering the maximum allowable variation is +2 mm.

There may be excess variability in your process.

Note: Test Results for Xbar Chart of Supp2

TEST 1. One point more than 3.00 standard deviations from center line.

Test Failed at points: 2, 14

* WARNING

* If graph is updated with new data, the results above may no

* longer be correct.

References by www.minitab.com

Box-Cox Transformation

Performs a Box-Cox procedure for process data used in control charts. To use Box-Cox, the data must be positive.

When you ask Minitab to estimate lambda, you get graphical output. See Box-Cox Transformation − Graphical Output for an explanation of the output.

The Box-Cox transformation can be useful for correcting both nonnormality in process data and subgroup process variation that is related to the subgroup mean. Under most conditions, it is not necessary to correct for nonnormality unless the data are highly skewed. Wheeler [31] and Wheeler and Chambers [30] suggest that it is not necessary to

transform data that are used in control charts, because control charts work well in situations where data are not normally distributed.

They give an excellent demonstration of the performance of control charts when data are collected from a variety of nonsymmetric distributions.

Minitab provides two Box-Cox transformations: a standalone command, described in this section, and a transformation option provided with all control charts, except the Attributes charts. You can use these procedures in tandem. First, use the standalone command as an exploratory tool to help you determine the best lambda value for the transformation. Then,

when you enter the control chart command, use the transformation option to transform the data at the same time you draw the chart.

Dialog box items

All observations for a chart are in one column: Choose if data are in one or more columns, then enter the columns.

Subgroup sizes: Enter a number or a column of subscripts.

Observations for a subgroup are in one row of columns: Choose if subgroups are arranged in rows across several columns, then enter the columns. <Options>

Data − Box-Cox Transformation

Use this command with subgroup data or individual observations. Structure individual observations down a single column. Structure subgroup data in a single column or in rows across several columns − see Data for examples. When you include or exclude rows using control chart options > Estimate, Minitab only uses the non-omitted data to find lambda.

To do a Box-Cox transformation

Example of Box-Cox transformation

The data used in the example are highly right skewed, and consist of 50 subgroups each of size 5. If you like, you can look at the spread of the data both before and after the transformation using Graph > Histogram.

1 Open the worksheet BOXCOX.MTW.

2 Choose Stat > Control Charts > Box-Cox Transformation.

3 Choose All observations for a chart are in one column, then enter Skewed.

4 In Subgroup sizes, enter 5.

5 Click Options. Under Store transformed data in, enterC2. Click OK in each dialog box.

Interpreting the results

The Lambda table contains an estimate of lambda (0.039501) and the best value

(0.000000), which is the value used in the transformation. The Lambda table also includes the upper CI (0.292850) and lower CI (−0.207308), which are marked on the graph by vertical lines.

Although the best estimate of lambda is a very small negative number, in any practical situation you want a lambda value that corresponds to an understandable transformation, such as the square root (a lambda of 0.5) or the natural log (a lambda of 0). In this example, 0 is a reasonable choice because it falls within the 95% confidence interval. Therefore, the natural log transformation may be preferred to the transformation defined by the best estimate of lambda.

The 95% confidence interval includes all lambda values which have a standard deviation less than or equal to the horizontal line. Therefore, any lambda value which has a standard deviation close to the dashed line is also a reasonable value to use for the transformation. In this example, this corresponds to an interval of − 0.207308 to 0.292850.

Thank you for referance by www.minitab.com

Performs a Box-Cox procedure for process data used in control charts. To use Box-Cox, the data must be positive.

|

| Box-Cox Transformation |

The Box-Cox transformation can be useful for correcting both nonnormality in process data and subgroup process variation that is related to the subgroup mean. Under most conditions, it is not necessary to correct for nonnormality unless the data are highly skewed. Wheeler [31] and Wheeler and Chambers [30] suggest that it is not necessary to

transform data that are used in control charts, because control charts work well in situations where data are not normally distributed.

They give an excellent demonstration of the performance of control charts when data are collected from a variety of nonsymmetric distributions.

Minitab provides two Box-Cox transformations: a standalone command, described in this section, and a transformation option provided with all control charts, except the Attributes charts. You can use these procedures in tandem. First, use the standalone command as an exploratory tool to help you determine the best lambda value for the transformation. Then,

when you enter the control chart command, use the transformation option to transform the data at the same time you draw the chart.

Dialog box items

All observations for a chart are in one column: Choose if data are in one or more columns, then enter the columns.

Subgroup sizes: Enter a number or a column of subscripts.

Observations for a subgroup are in one row of columns: Choose if subgroups are arranged in rows across several columns, then enter the columns. <Options>

Data − Box-Cox Transformation

Use this command with subgroup data or individual observations. Structure individual observations down a single column. Structure subgroup data in a single column or in rows across several columns − see Data for examples. When you include or exclude rows using control chart options > Estimate, Minitab only uses the non-omitted data to find lambda.

To do a Box-Cox transformation

Example of Box-Cox transformation

The data used in the example are highly right skewed, and consist of 50 subgroups each of size 5. If you like, you can look at the spread of the data both before and after the transformation using Graph > Histogram.

1 Open the worksheet BOXCOX.MTW.

|

| Box-Cox transformation-1 |

|

| Box-Cox transformation |

|

| Box-Cox transformation-3 |

|

| Box-Cox transformation-4 |

|

| Box-Cox transformation chart |

The Lambda table contains an estimate of lambda (0.039501) and the best value

(0.000000), which is the value used in the transformation. The Lambda table also includes the upper CI (0.292850) and lower CI (−0.207308), which are marked on the graph by vertical lines.

Although the best estimate of lambda is a very small negative number, in any practical situation you want a lambda value that corresponds to an understandable transformation, such as the square root (a lambda of 0.5) or the natural log (a lambda of 0). In this example, 0 is a reasonable choice because it falls within the 95% confidence interval. Therefore, the natural log transformation may be preferred to the transformation defined by the best estimate of lambda.

The 95% confidence interval includes all lambda values which have a standard deviation less than or equal to the horizontal line. Therefore, any lambda value which has a standard deviation close to the dashed line is also a reasonable value to use for the transformation. In this example, this corresponds to an interval of − 0.207308 to 0.292850.

Thank you for referance by www.minitab.com